EDM Labs Ltd.

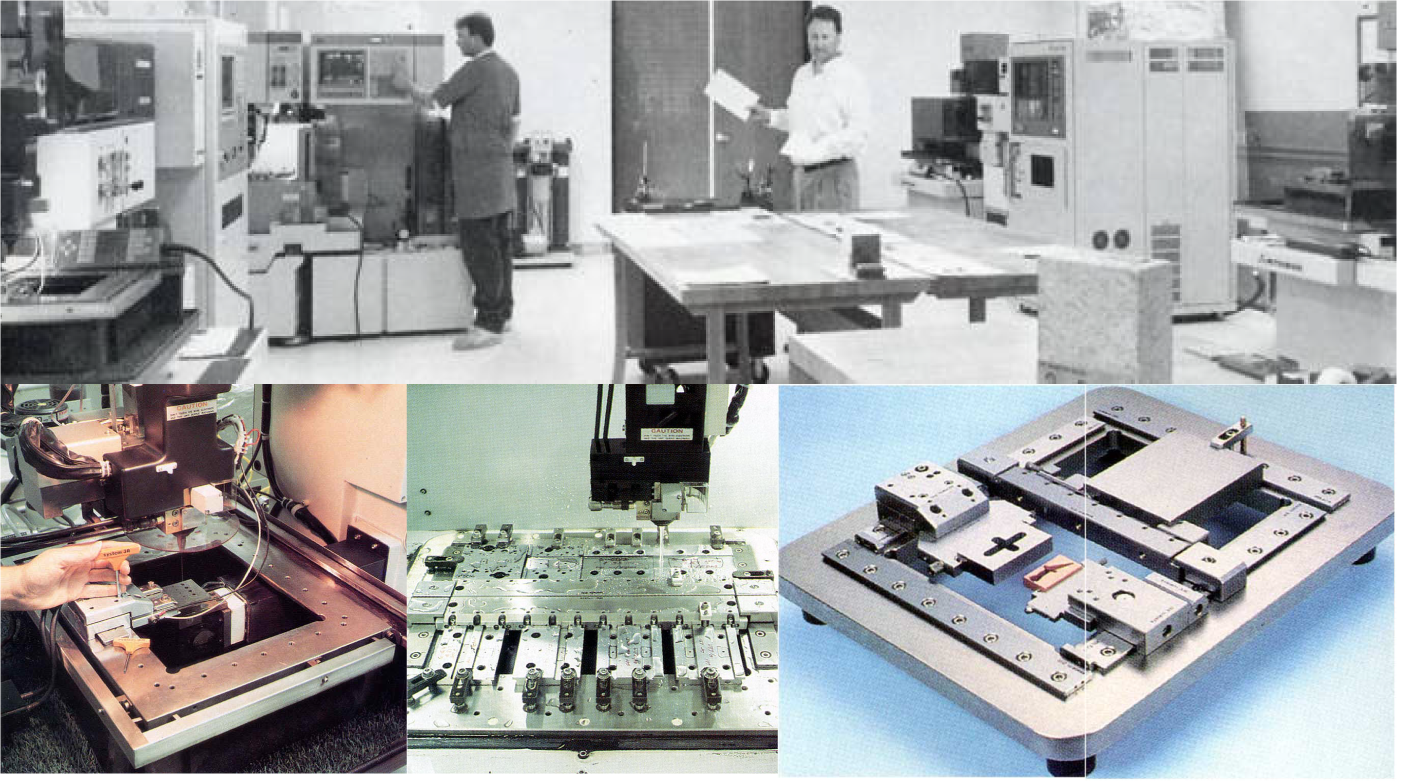

We deliver precise, accurate, and dependable high-quality EDM services by our specially trained and certified technicians right here in Silicon Valley.

We deliver precise, accurate, and dependable high-quality EDM services by our specially trained and certified technicians right here in Silicon Valley.

Family and Veteran owned and operated EDM machine shop. Serving the Bay Area for more than 30 years. Specially trained and certified technicians. Extremely high accuracy. Minimal turn-around time. High quality services and parts delivered. All work is examined with calibrated inspection equipment.

Wire EDM uses an electrically charged wire electrode to vaporize and melt electrically conductive work pieces, to very smooth and accurate surfaces. The diameter of the wire electrode we use ranges from as small as .0015", and up to .012".

Sinker EDM uses an electrically charged Copper, Graphite or combination to vaporize and melt electrically conductive work pieces, to very smooth and accurate surfaces.

EDM drilling uses a precision brass tube as a drill bit that drills a hole by vaporizing and melting electrically conductive material. The diameter of the electrodes we use are anywhere from .004 to .256 of an inch in diameter.

EDM Labs machines shop services.

Anti Electrolysis With Power Master Control and Corner Master

20 Inches Submerged with Auto Wire Thread Power Z

29.5 X 19.6 X 20 / 3.0 UV

Anti Electrolysis With FS Power Supply

Submerged with Auto Wire Thread Power Z

9.847 X 11.814 X 6.9

Anti Electrolysis With Power Master Control and Corner Master

Submerged with Auto Wire Thread Power Z

13.7 X 9.8 X 8.6

004 to .256 Diameter Electrodes

8.1 X 12.2 X 11.5

16 Position ATC C Axis

17.72 X 13.78 X 13.78

20 Power to 200 Power

2 X 4 Stage

Maximum work piece dimensions (W) 29.5 X (D) 19.6 X (H) 20.00 inches thick with tapers up to 45 degrees.

Wire diameters range from .003 to .013.

EDM Drill hole sizes down to .005 diameter. We have drilled a .035 diameter hole through 13 inches thick 304 Stainless Steel.

Super fine surface finishing completely burr-free. We have done a 3 Finish in CD650 Carbide.

Extremely high accuracy is possible with minimal turn-around time! We have held tolerances of +/-.00005 of an inch.

EDM LABS LTD. examines all work using calibrated inspection equipment. Calibration records on hand. Specially trained and certified technicians available to help you!

Send us a message, question, or request a quote